Orientech’s automation expertise has strong roots in the cosmetic industry. Multinational partners faced several complexities in their attempts to automate their production processes — often resulting from sorting, orienting, and assembling third party components.

We implement many processes that allow for optimized productivity.

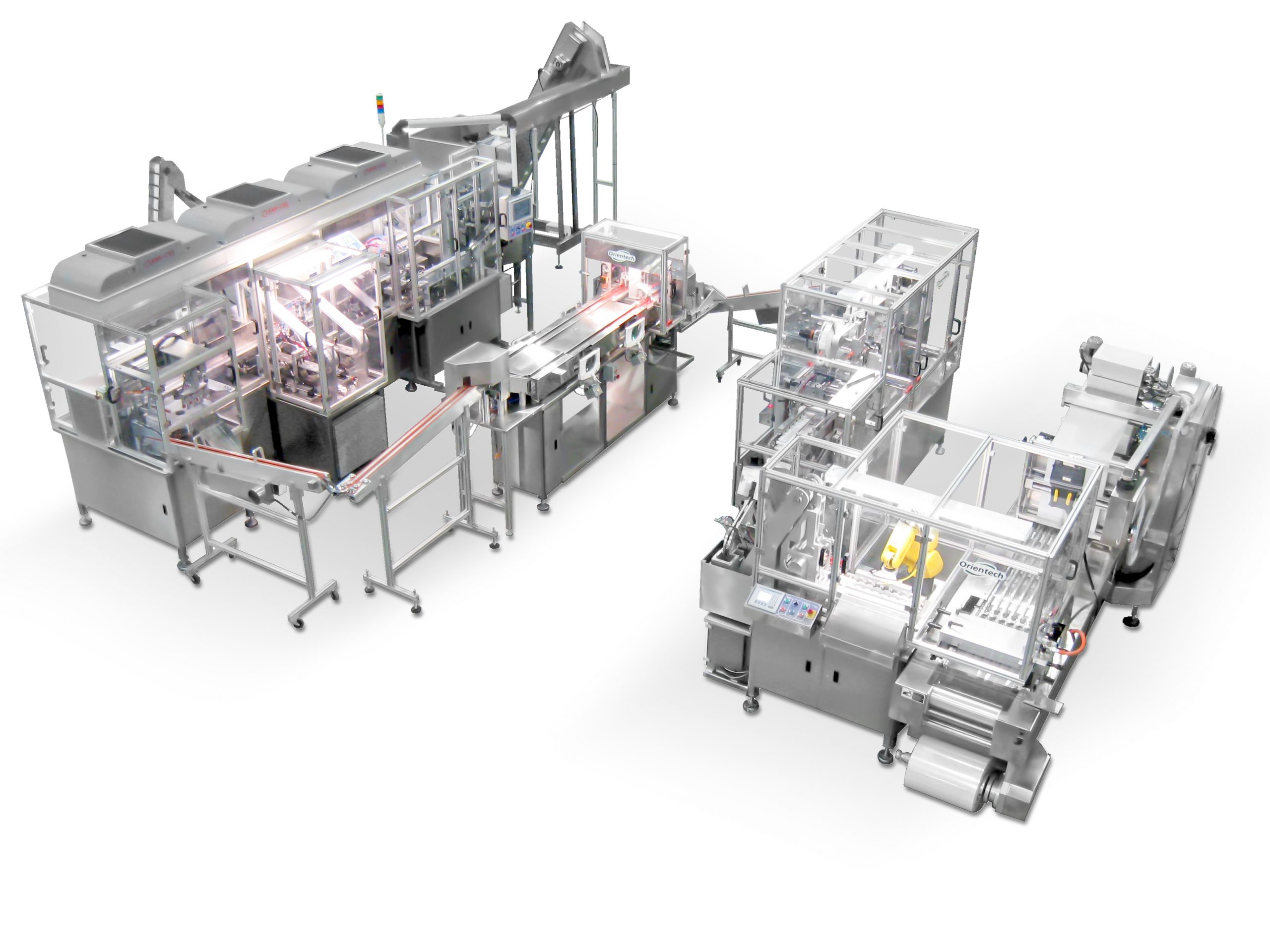

Our extensive proprietary know-how in feeding, sorting, orienting, and positioning parts, makes us the perfect partner to finalize component assembly. Orientech’s pre-assembly machines allow us to have control of the components during the entire process. The feeding, sorting, orienting, and positioning parts are often underestimated when designing an assembly line. Mastering these led Orientech to develop and market various custom automated and semi-automated systems that are becoming essential parts of the feeding, positioning, labeling, counting, coding, and packaging for a wide variety of cosmetic products.

Depending on the needs and standards of your company, we design flexible and fast systems to meet your expectations. Given the very high level of adaptability of our supply systems, you can also select the rate of production according to your preferences, at any desired time.

Our unique combination of expertise and innovation makes Orientech the only North American manufacturer with the capacity to assemble the wide variety of components used in today’s cosmetics industry.

We have acquired a comprehensive understanding of the automation processes used in the manufacture of cosmetics.

Here are some of our successful realizations:

- Mascara assembly machine

- Powder makeup mirror assembly machine

- Compact powder assembly equipment

- Lipstick and lip gloss assembly machines

- Dropper bottle assembly machine

We only propose solutions to your needs and wants if they are feasible and fit in your timeline. We understand the risks involved with our partners not meeting deadlines and the importance of having the flexibility required to compete, while adapting, in the highly competitive cosmetics industry.