How Orientech Transformed Plastics Manufacturing with Automation.

In today’s fast-paced manufacturing world, the plastics industry faces growing pressure to produce faster, with greater precision, and at lower cost — all while maintaining consistent quality. Orientech stepped in with a simple goal: to make automation smarter, more adaptable, and more human-centered.

The Challenge: Manual Processes and Inconsistent Output

Before automation, many plastics manufacturers relied on manual or semi-automated systems. These processes often led to inconsistent product quality, downtime between production runs, and difficulty scaling production to meet demand. Operators had to adjust machines manually, which increased the risk of human error and reduced overall efficiency.

The Orientech Approach : Automation Built Around People

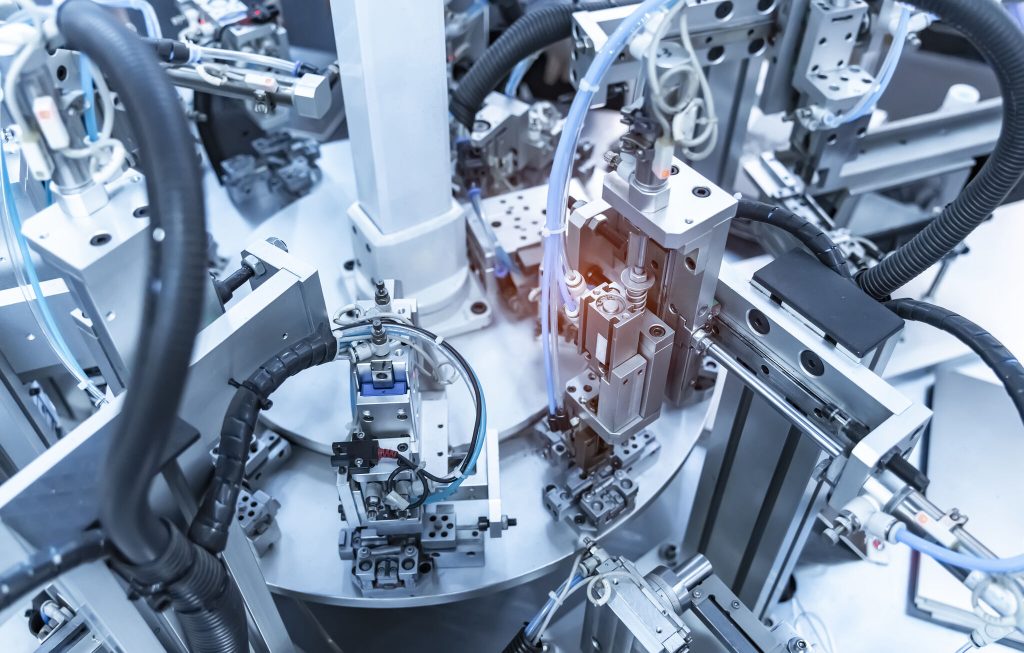

Orientech didn’t just add robots and automation — we redesigned the process from the ground up.

Our team worked closely with plant engineers and operators to understand their workflow, bottlenecks, and production goals. The result? A fully integrated, modular automation system that adapts to the client’s specific needs — whether for part handling, assembly, or quality inspection.

Each system is built to fit, not forced to fit.

The Transformation: From Downtime to Uptime

Once installed, the Orientech system immediately delivered measurable improvements:

Cycle times reduced by up to 40%

Defect rates cut by more than half

Setup and changeover times reduced dramatically

Real-time production data allowing proactive maintenance and faster decision-making

Operators now manage intuitive, touchscreen-based controls rather than complex manual adjustments — freeing up time to focus on optimization and continuous improvement.

Sustainability Through Efficiency

Automation isn’t just about speed — it’s about smarter use of resources.

By optimizing cycle times and reducing scrap, Orientech’s systems help plastics manufacturers lower energy consumption and minimize material waste, contributing to a more sustainable production model.

A Partnership That Scales

What makes Orientech unique is our ongoing commitment after installation.

Our local support team ensures that clients continue to evolve their automation capabilities as their business grows. Whether integrating new molds, product lines, or data-driven upgrades, Orientech systems are designed to scale.

Automation Made Simple — Automation That Works

The result speaks for itself: plastics manufacturers that once struggled with inefficiency are now operating smoother, faster, and smarter.

At Orientech, we believe automation should empower people, not replace them — and that’s exactly what we’ve achieved.

Ready to take your plastics manufacturing to the next level ?

Contact Orientech to explore how custom automation can redefine your productivity.

See original post