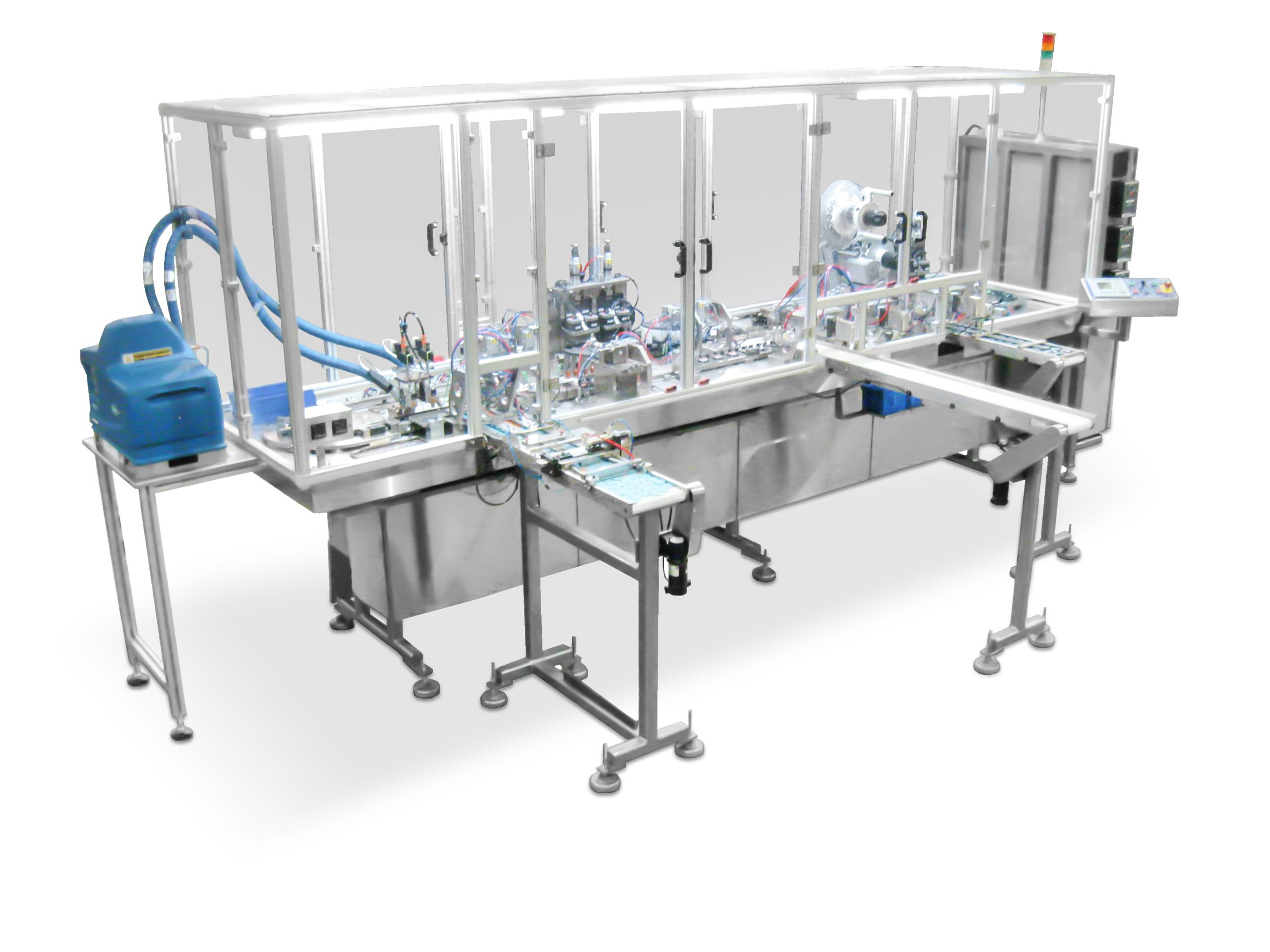

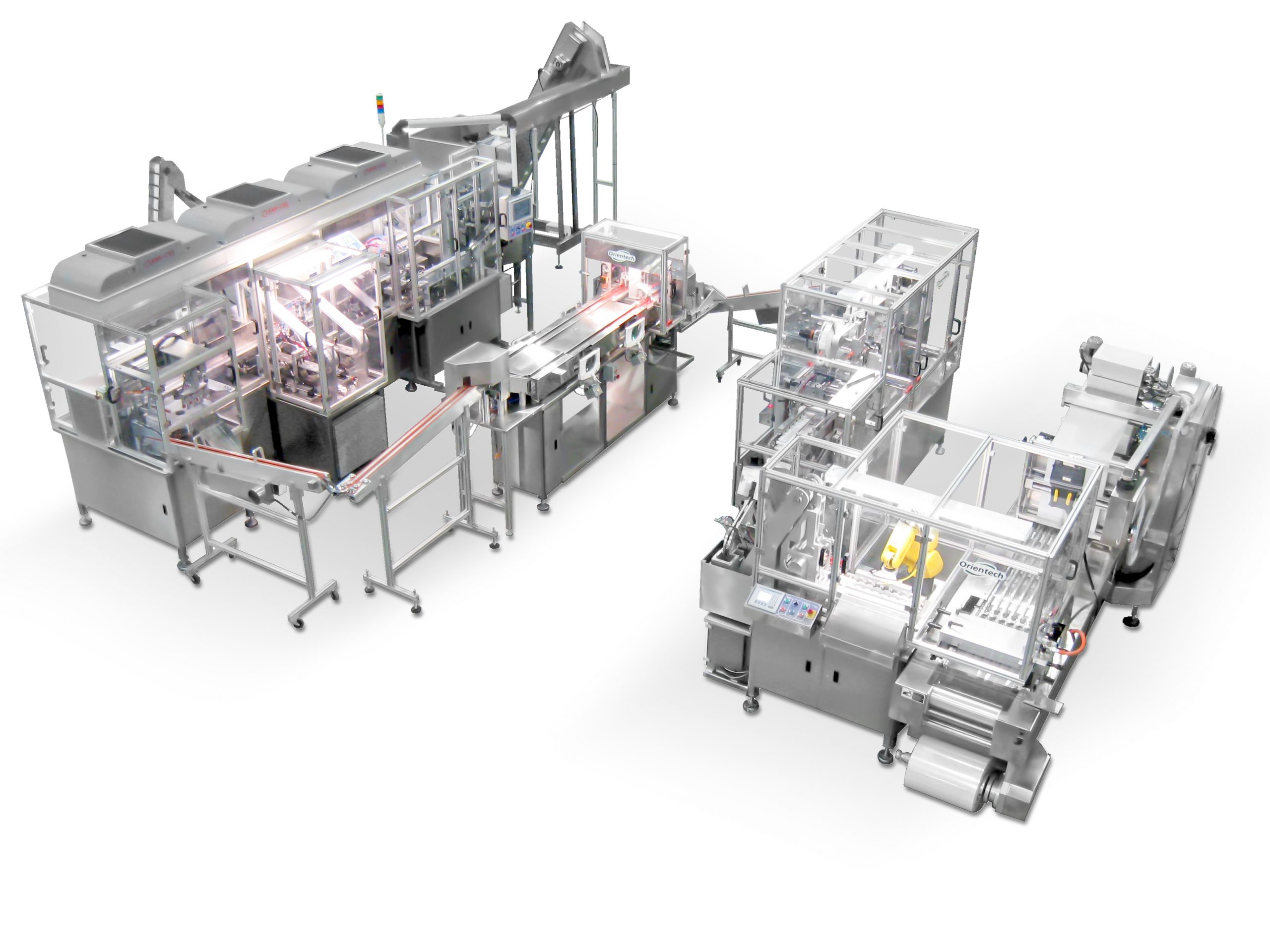

Custom assembly systems, with available quick-tool-change options, are designed and built to ensure minimal downtime when switching from models being assembled.

Turn-key automated assembly machines

COMPLICATED ASSEMBLIES MADE EASY

Orientech Turn-Key assembly machines may be fully automated, or semi-automated.

Semi-automated integration solutions are an excellent alternative when there are budget constraints and/or one to enter into automation to perform repetitive and precise operations in your process.

Orientech assembly systems are available with different technologies to adapt to requirements within budgetary needs for your automation integration :

- Placement

- Insertion

- Pressure

- Indexing motion rotary action tables

- Continuous motion rotary action tables

- Indexing motion linear systems

Components may be secured with various solutions, including:

- Adhesive application solutions

- Crimping solutions

- Slitting solutions

- Drilling solutions

- Tapping solutions

- Screwing solutions

- Welding solutions

- Ultrasonic sealing solutions

- Induction sealing solutions

To enhance efficiencies, whether it be for quality purposes, or for difficult to position components due to tight tolerances, visual inspection solutions are available to be used throughout the process for automated collation or rejection system.

While components or full assemblies are being manipulated by your automated assembly system, we recommend, for cost purposes, adding your marking, coding or labeling needs within the operations, such as :

- Marking solutions

- Coding solutions

- Labeling solutions

- Packaging solutions

Versatility designed into your Turn-Key Automated assembly machine to reduce downtime. Further investment for greater return on investment (ROI) is cost advantage allowing one to produce/assemble more than one SKU on the same equipment. Consider investing from the start to grow your revenues further using automation.

Some available features include :

- Interchangeable tooling

- Quick-change tooling solutions without the need to readjust settings

- Retooling options

- End-of-run product purge

- Clean-out points

Ease of operating your automation equipment is an important factor to consider, including controls. Customize your functions with a selection of touch-screen HMIs for users, and also include preventive maintenance schedules. Error messages may be programmed to help operators take actions prior to resuming operation, or for them to escalate to a supervisor.

Security is of great importance in any operation. Removing access to dangerous areas, with physical barriers, as well as automating stoppage in-case of a breach, are good manufacturing practices designed for everyone’s safety. Customize the safety and security levels of your automated assembly machine with a variety of technologies with controllers to communicate with all areas of your automated assembly machine, either for an E-STOP (Emergency Stop) or other reasons.

Common types of security systems Orientech integrates include :

- Safety Light Curtains

- Safety Laser Scanners

- Safety Interlock Systems

- Magnetic Lock Systems

- E-STOP Systems

- Safety Controller for E-STOPs and/or any other safety device