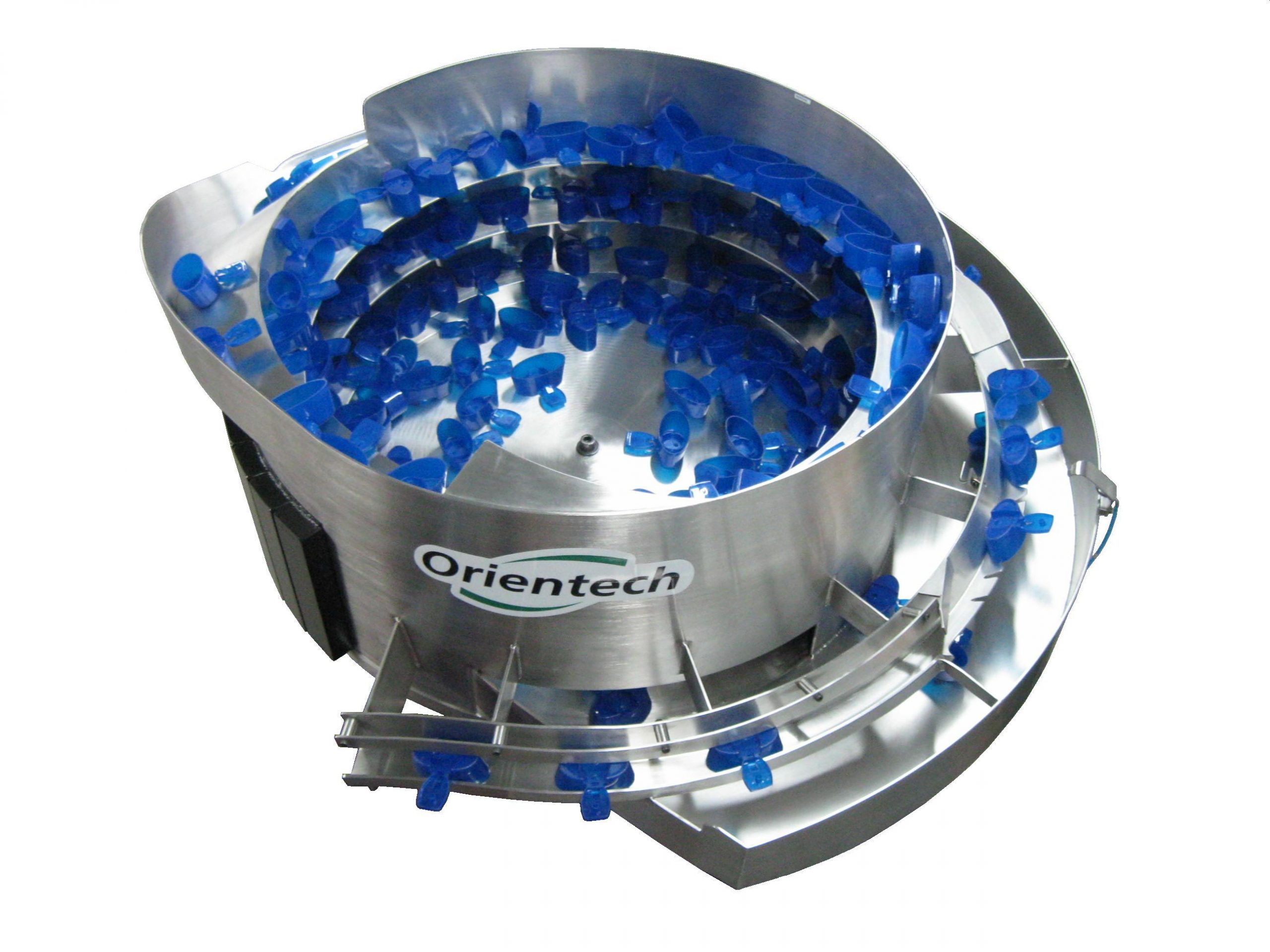

Orientech centrifugal feeders have been engineered to rapidly deliver a wide range of pieces at high speeds. Centrifugal applications are chosen depending on the part’s characteristics.

Orientech is renowned for providing solutions that will work as promised.

The design of a centrifugal system starts with your parts. The needs assessment is a critical part of the process. We highly recommend validating with our engineering team, the required output of a component prior to locking in the design the remainder of the line.

Orientech centrifugal feeders are designed to meet industry 4.0 standards and may communicate with your existing equipment.

Final design options vary, depending on the speed required, as well as the fragility of your parts, include :

- Diameter of centrifugal feeder

- Single disk centrifugal feeder

- Double disk centrifugal feeder

- Regulatory requirements, such as FDA

Typically centrifugal systems are ordered within a complete automated assembly system, or other Orientech solutions.

These may include bulk feed hoppers, elevators and orientation devices such as :

- Twist chute

- “C” chute

- Gauge rollers

- Conveyors

- Spacing wheels

Select material choices used in Orientech centrifugal feeders:

- Built on a rigid, welded and painted steel frame

- Available Stainless Steel for certain applications

- U.H.M.W. center disc

- Unique cast aluminum bowl

- hard anodized to protect against wear

- features a curved profile allowing the central feed disk to be set at infinitely variable angles to maximize feeding efficiency

- designed to accept larger than usual parts