Engineering with Soul : The Orientech Essence.

Innovation is at the core of what we do, but people are what drive it forward.

We are thrilled to announce an extraordinary collaboration with the talented Fahri (Yavuz Photo) and Jordan Hamelin.

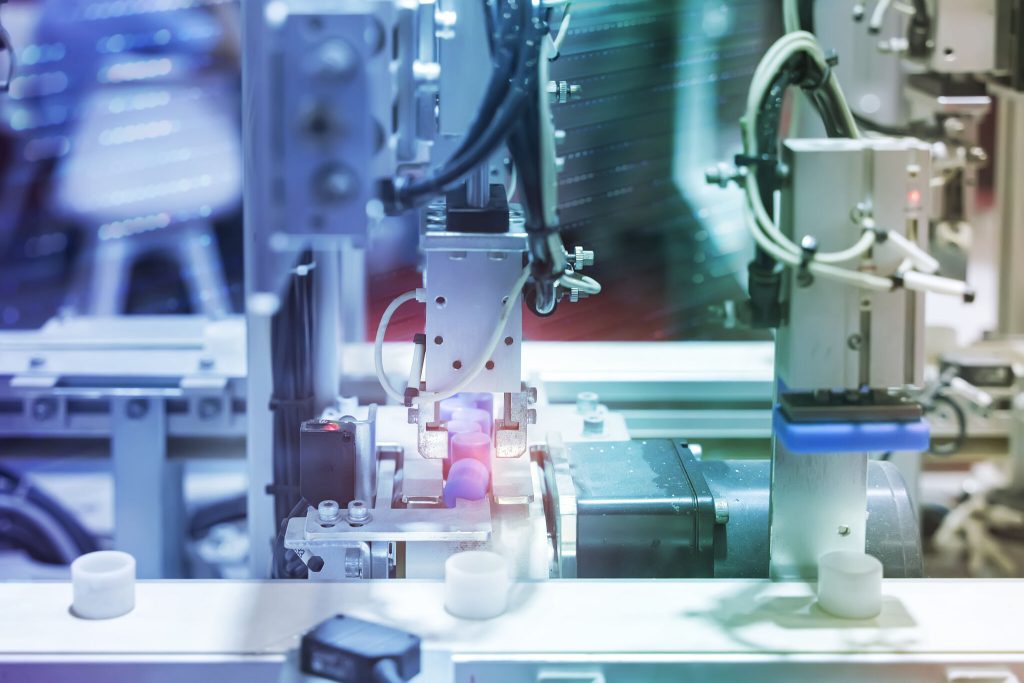

Together, we’ve been working on a new corporate video that captures the very essence of Orientech : our technical expertise, the precision of our systems, and above all, the energy of our team.

Beyond just showcasing our machines, this project highlights the commitment and craftsmanship that define us every day.

A huge thank you to Fahri and Jordan for their vision and creativity!

Partenaires de création / Creative Partners :

Fahri (Yavuz Photo) : yavuzphoto.ca & Jordan Hamelin : jordanhamelin.com

Stay tuned : the video will be available shortly…

____________________________________________________________________________________

L’ingénierie avec une âme : L’essence d’Orientech.

L’innovation est au cœur de ce que nous faisons, mais ce sont les gens qui la propulsent.

Nous sommes fébriles de vous annoncer une collaboration extraordinaire avec les talentueux Fahri (Yavuz Photo) et Jordan Hamelin.

Ensemble, nous avons travaillé à la création d’une nouvelle vidéo corporative qui capture l’essence même d’Orientech : notre savoir-faire technique, la précision de nos systèmes, et surtout, l’énergie de notre équipe.

Plus qu’une simple présentation de nos machines, ce projet met en lumière l’engagement et l’expertise qui définissent notre quotidien.

Un immense merci à Fahri et Jordan pour leur vision et leur créativité !

Restez à l’affût : la vidéo sera disponible sous peu…

{hashtag|#|Orientech} {hashtag|#|Automation} {hashtag|#|Innovation} {hashtag|#|Manufacturing} {hashtag|#|BehindTheScenes} {hashtag|#|Expertise} {hashtag|#|IndustrialDesign} {hashtag|#|VideoProduction}